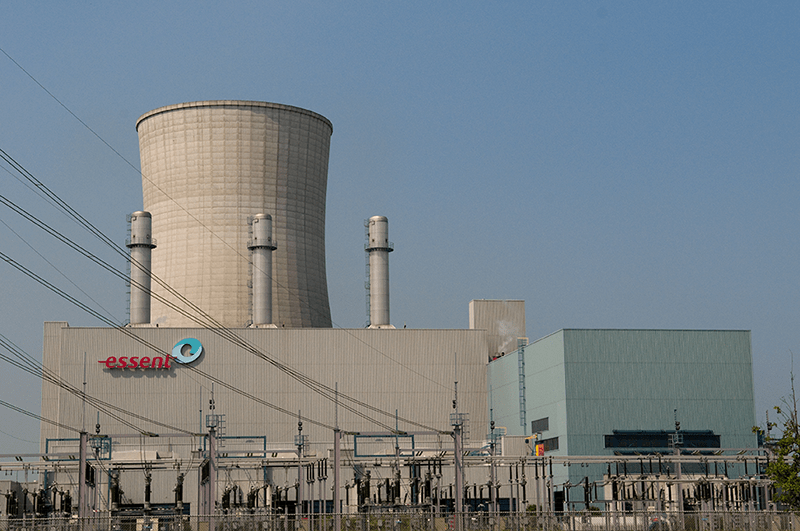

Essent Energy (a subsidiary of RWE) is one of the leading energy companies in Europe with more than 18 production facilities.

The Task

As a result of deregulation of the energy market, Essent Energy was forced to improve its production capacity and to reduce maintenance costs.

The Approach

A Maintenance Excellence program based on Value Driven Maintenance (VDM) was introduced. One of the key objectives was to standardize performance indicators and to monitor individual power plants. Instead of starting from ground zero, Essent decided to use the standard KPI dashboard functionality of the VDM Control Panel.

Mainnovation standardized the maintenance and engineering-related work processes, using the VDM Process Map for this purpose. Next, this standardized way of working was implemented in a single Infor EAM environment for all production facilities. The next logical step was to implement a KPI Dashboard in Infor EAM in order to monitor and compare the performance of the individual sites.

Mainnovation’s Added Value

The improvement program was successful. Productivity rose by an average of 5%, while annual costs were reduced by € 10 million.

Jan Boone (Essent Energy, responsible Project Manager): “The VDM Control Panel makes it possible to quickly identify weak areas. All the data required for analysis purposes are defined in advance, including KPIs and graphs. The dashboard provides up-to-date information on a daily basis. At a single glance it is clear whether availability is on target and, if not, an analysis can be performed to find out why not. In the morning I can immediately trace back any problems that occurred and I can immediately see which factors negatively affected performance. Furthermore, I can see whether the actual costs deviate from the estimated costs. Before the introduction of the VDM Control Panel we were forced to track down and analyze each problem all over again every time. Today, we have real-time insight into the current situation and any deviations.

Productivity rose by 5%, annual costs reduced by € 10 million

more cases

-

![]()

The organization and processes were professionalized on the basis of the VDMXL Process Map.

Energy & Utilities -

![]()

-

![]()

Social